The Applied Analytics #OMA is the ideal multi-component instrument for analyzing true NOX (NO + NO2) in emissions and critical process applications.

The release of nitrogen oxides (NOX) to the atmosphere causes the formation of nitric acid rain and depletes the ozone layer. These emissions are heavily regulated around the world. Industrial combustion sites must report the amount of NOX exiting their stack and often implement processes like DeNOX to reduce these emissions.

Applications

The release of nitrogen oxides (NOx) to the atmosphere causes the formation of nitric acid rain and depletes the ozone layer. These emissions are heavily regulated around the world. Industrial combustion sites must report the amount of NOx exiting their stack and often implement processes like DeNOx to reduce these emissions.

Proven Applications

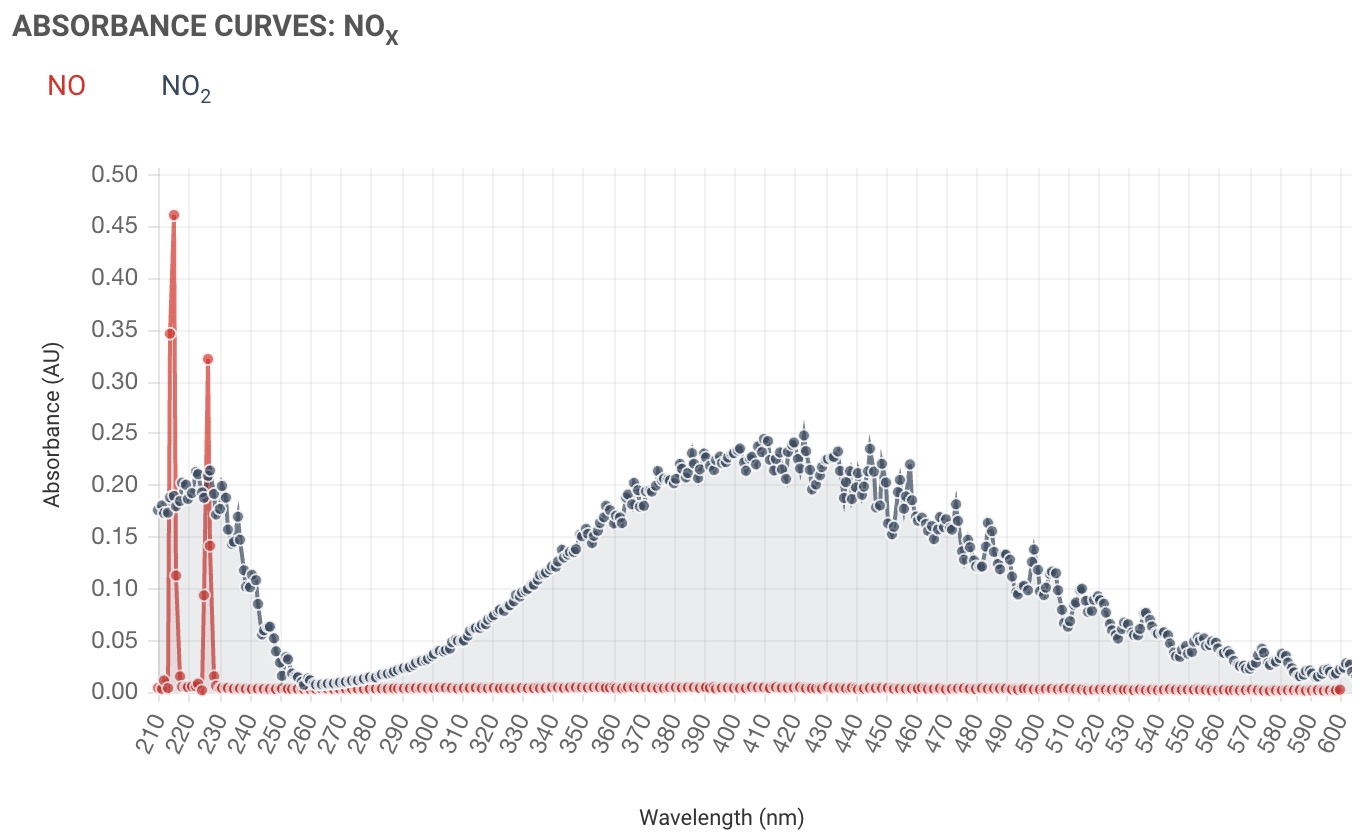

NOX Absorbance Spectra

To measure true NOX, the OMA individually measures NO and NO2 concentrations. The powerful multi-component software isolates the distinctive absorbance curves of the analytes and mathematically isolates their structures from the total sample absorbance. In accordance with Beer-Lambert Law, the OMA correlates the height of these curves directly to real-time concentrations. The NOX reading is a simple sum of the two measurements.

Sampling

The OMA is built for direct analysis of the hot/wet sample, thus simplifying the scope of the sample system and retaining high sample integrity. From our vast experience in sampling design, we know that applications can be similar but are rarely identical. For this reason, we design and build sample conditioning systems on a project basis, working from the process to the drawing board.

General

Measurement Principle | Dispersive ultraviolet-visible (UV-Vis) absorbance spectrophotometry | |

Detector | nova II™ UV-Vis diode array spectrophotometer | |

Spectral Range | 200-800 nm | |

Light Source | Pulsed xenon lamp (average 5 year lifespan) | |

Signal Transmission | 600 μm core 1.8 meter fiber optic cables | |

Path Length | Application-dependent | |

Sample Conditioning | Custom design per application | |

Analyzer Calibration | If possible, analyzer is factory calibrated with certified calibration fluids; no re-calibration required after initial calibration; measurement normalized by Auto Zero | |

Reading Verification | Simple verification with samples and self-check diagnostic | |

Human Machine Interface | Industrial controller with touch-screen LCD display running ECLIPSE™ Software | |

Data Storage | Solid State Drive | |

OPERATING CONDITIONS | ||

Analyzer Environment | Indoor/Outdoor (no shelter required) | |

Ambient Temperature | Standard: 0 to 35 °C (32 to 95 °F) | |

Sample Temperature | Standard: -20 to 70 °C (-4 to 158 °F) | |

Sample Pressure | Using standard flow cell: 206 bar (3000 psi) | |

UTILITIES | ||

Electrical | 85 to 264 VAC 47 to 63 Hz | |

Power Consumption | 45 watts | |

OUTPUTS | ||

Standard Outputs | 1x galvanically isolated 4-20mA analog output per measured analyte(up to 3; additional available by upgrade) | |

Optional Outputs | Modbus TCP/IP; RS-232; RS-485; Fieldbus; Profibus; HART; | |

Performance

NOX Accuracy | |

0-100 ppm | ±5 ppm |

0-10,000 ppm | ±2% full scale or 5ppm* |

0-100% | ±2% full scale |

*Whichever larger. | |

Certifications

Standard Design | General Purpose |

Available Options | ATEX, IECEx, EAC, PESO, JPN, KTL |

Please inquire with your sales representative for additional certifications (CSA, FM etc.). | |

| Messages | |

| Name | |